J-STD-001

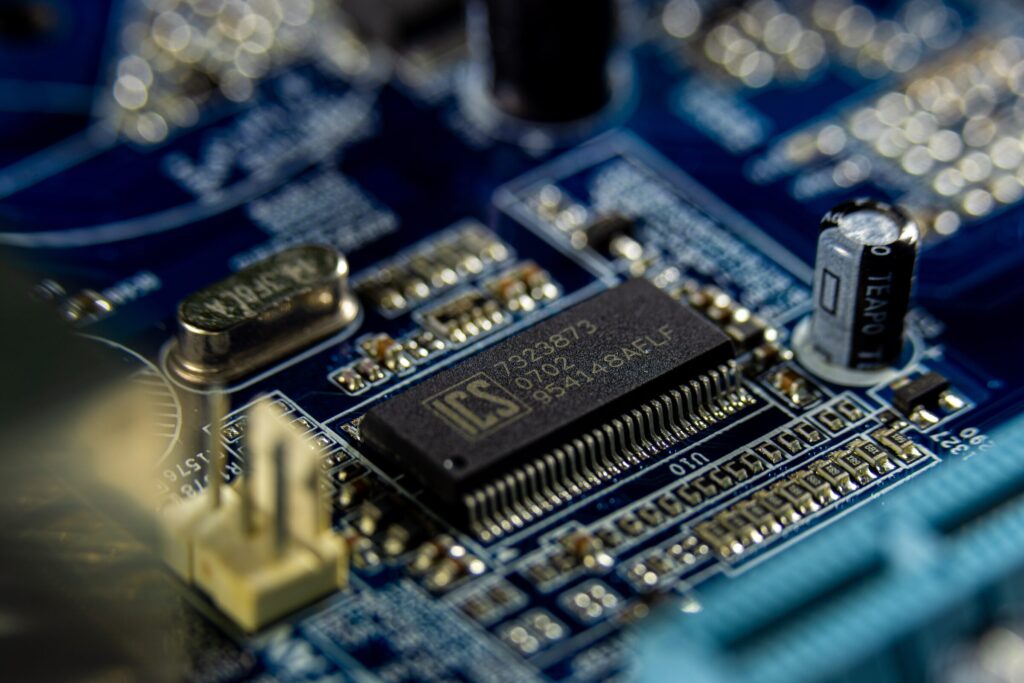

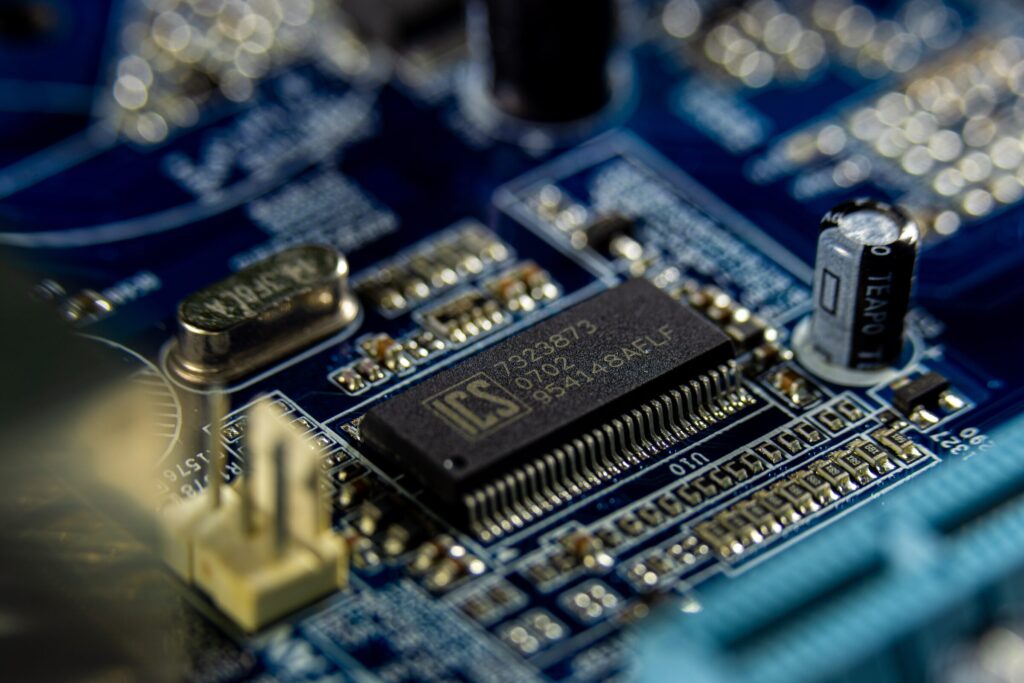

IPC J-STD-001 is a globally recognized standard published by the IPC that sets the requirements for the manufacture of electronic assemblies. It specifies the materials, methods, and verification criteria for producing high-quality soldered interconnections and components in electronic assemblies.

J-STD-001 covers a wide range of topics related to electronic assembly manufacturing, including soldering, component mounting, wire and terminal assembly, and cleaning. The standard provides criteria for evaluating workmanship, performance, and reliability of electronic assemblies.

J-STD-001 is used in a variety of industries, including aerospace, military, medical, and consumer electronics. Compliance with this standard helps ensure that electronic assemblies are manufactured and inspected to a high standard, promoting safety, reliability, and performance. It is an essential tool for quality control and inspection purposes in the electronics industry.

IPC A-610

The IPC-A-610 is a widely recognized standard developed by the IPC that sets the acceptance criteria for electronic assemblies. It provides guidelines for the visual inspection of printed circuit board assemblies and other electronic components, including solder joints, component placement, and other aspects of assembly workmanship.

The IPC-A-610 is an important standard that helps establish a common language between customers and suppliers of electronic assemblies. By following the criteria outlined in the standard, manufacturers can ensure that their finished products meet the required quality standards. The standard includes illustrations and photographs to aid in consistent interpretation and application of the criteria, making it an essential tool for quality control and inspection purposes in the electronics industry.

The IPC-A-610 standard is widely used in various industries, including automotive, aerospace, defense, medical, and consumer electronics. Its adoption ensures that electronic assemblies are manufactured and inspected to a high standard, promoting safety, reliability, and performance.

7711 / 7721

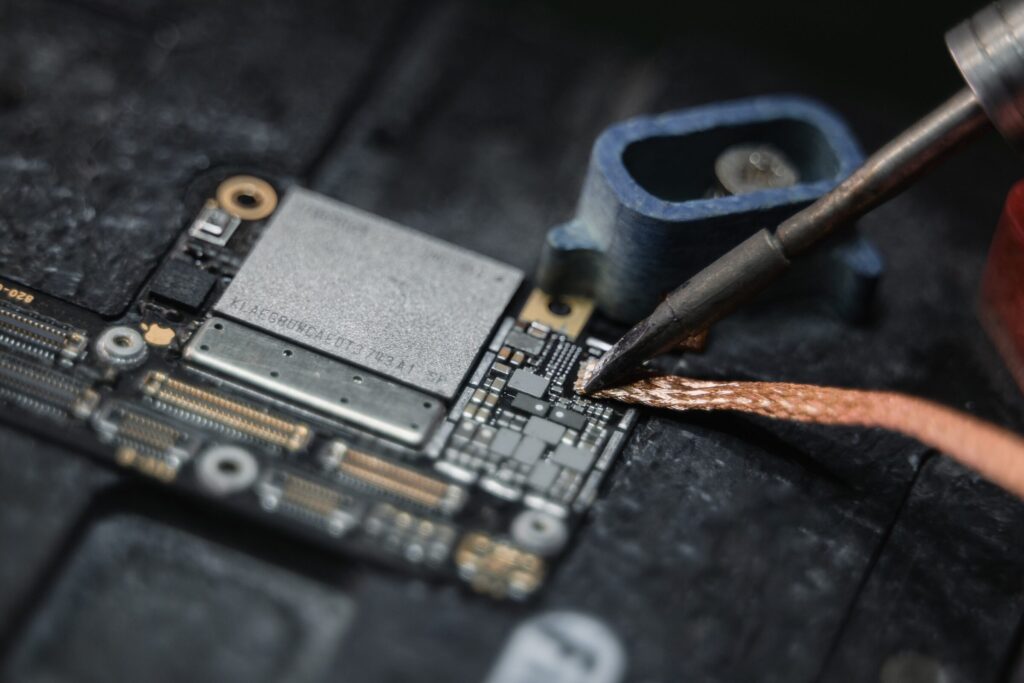

IPC 7711/7721 is a pair of globally recognized standards published by the IPC that cover the repair and rework of electronic assemblies. These standards provide guidelines and procedures for the restoration of printed circuit board assemblies and electronic assemblies that have been damaged, reworked, or otherwise require modification.

IPC 7711/7721 covers a wide range of topics related to electronic assembly repair and rework, including the removal and replacement of components, board repair, and modification of assemblies. The standard provides criteria for evaluating the quality of repair and rework, including methods for inspecting and testing the repaired or reworked assembly.

IPC 7711/7721 is used in a variety of industries, including aerospace, military, medical, and consumer electronics. It provides a common language and set of guidelines for repair and rework procedures, ensuring consistent and high-quality results. The standards are also an essential tool for quality control and inspection purposes in the electronics industry.

IPC J-STD-001 Space Addendum is an extension of the IPC J-STD-001 standard that is specifically tailored for the manufacture of electronic assemblies for space applications. The addendum provides additional requirements and guidelines for the design, manufacture, and testing of electronic assemblies for spaceflight. These additional requirements help to ensure the reliability and performance of electronic assemblies in harsh space environments.

The IPC J-STD-001 Space Addendum covers a wide range of topics, including component selection and usage, assembly processes, materials selection and testing, and inspection and testing requirements. It provides specific requirements for assembly workmanship, including the use of specialized materials and processes, such as conformal coating and hermetic sealing. The addendum also includes requirements for testing and verification of electronic assemblies, including environmental testing and electrical testing.

The IPC J-STD-001 Space Addendum is used in the aerospace and defense industries, as well as in other industries that require high-reliability electronic assemblies. The requirements in the addendum help to ensure that electronic assemblies are designed and manufactured to withstand the extreme conditions of spaceflight and perform reliably throughout the mission. By adhering to the guidelines in the IPC J-STD-001 Space Addendum, manufacturers can produce high-quality, reliable electronic assemblies that meet the needs of a range of industries, including space exploration, communications, and satellite technology.

At GNOMER TECHNOLOGY, we specialize in delivering high-quality IPC training and certification services. We understand that interruptions in production can have a significant impact on your business, which is why we offer flexible on-site training options tailored to meet your needs. Our team also provides recertification programs to ensure that you maintain your certification and stay up-to-date with the latest industry standards. With our expert guidance, you can enhance your knowledge and skills, improve your productivity, and ensure the highest quality standards for your products.

We offer free consultations and evaluations to help determine the best solutions for your needs. Our team is dedicated to providing you with exceptional service and expert advice, and we take pride in delivering high-quality results in a timely manner. Our turnaround time is fast and tailored to the specific requirements of each job, which will be discussed and agreed upon in advance to ensure that you receive the best possible outcome. We look forward to the opportunity to assist you and provide you with the support you need to achieve your goals.

We cater to a wide range of industries, including medical, aerospace, military, and various other sectors. Our expertise in these fields enables us to provide specialized solutions that meet the unique needs and requirements of each industry. Whether you need custom products, specialized equipment, or expert advice, our team is ready to assist you with the highest level of professionalism and attention to detail. We take pride in our ability to deliver exceptional service and quality results, and we look forward to the opportunity to work with you.

Fill in the form below and we will get back to you as soon as possible.